By clicking SUBMIT, you agree to the processing of personal data and to the privacy policy

iFarm Berries Vertical Farming Technology

Automated Technology for year-round cultivation of full-flavored strawberries on vertical hydroponic farms

Controlled-environment

agriculture

agriculture

Year-round automated

strawberry cultivation

strawberry cultivation

Premium-quality product

Pollination

with bumblebees

with bumblebees

Who can benefit from iFarm Berries technology

Improve your country’s quality of life with innovative technology

Regional development institutions

Delight your guests with delicious, eye-catching fresh strawberries all year round

Hospitality business

Retail

Premium-quality product with short supply chain

Secure year-round production with no climate risks

Agribusiness

Why strawberries grown with iFarm technology taste better

-

Berries are harvested ripe, so they contain a lot of natural sugars, and are rich

Berries are harvested ripe, so they contain a lot of natural sugars, and are rich

in vitamins C, B1, B2, B5, B6, B9. -

iFarm’s software offers recipes for growing the best varieties, selected for taste characteristics, yield, and reliability

iFarm’s software offers recipes for growing the best varieties, selected for taste characteristics, yield, and reliability -

Strawberries grown with iFarm Berries technology do not need to be washed - no pesticides are needed indoors

Strawberries grown with iFarm Berries technology do not need to be washed - no pesticides are needed indoors -

Strawberries from urban farms can be delivered to customers within a couple hours of being harvested

Strawberries from urban farms can be delivered to customers within a couple hours of being harvested

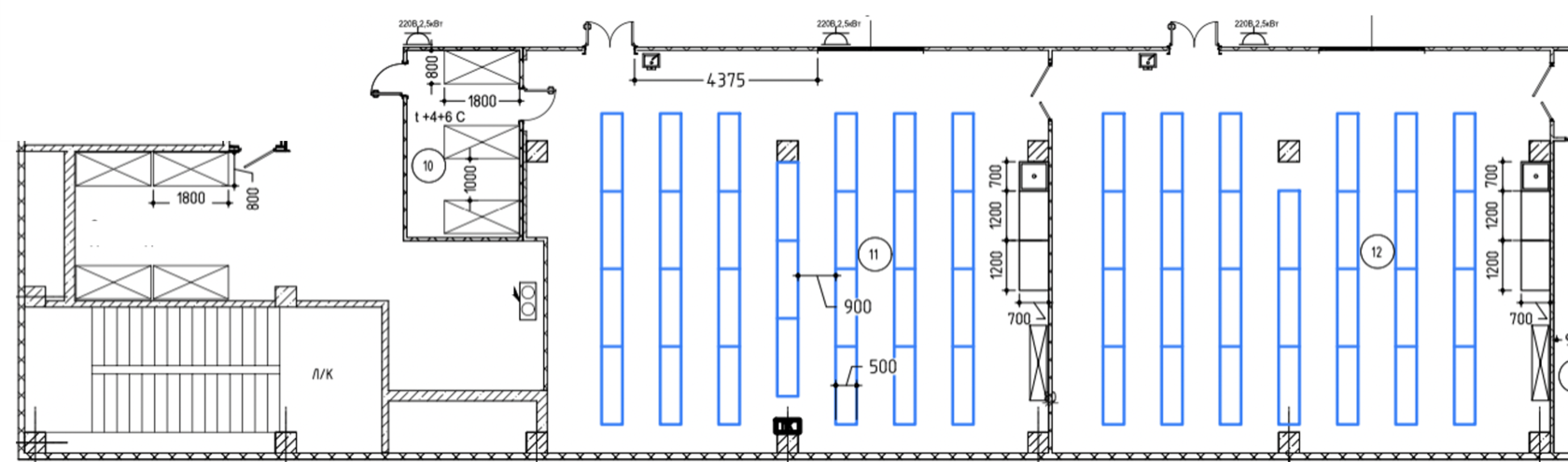

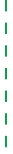

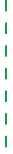

Fully-equipped vertical farming system

delivered and installed

iFarm Berries technology includes all the necessary hardware and automation modules, software, and a consumables kit

Seeding Area

Manual or automated ergonomic process with all the materials provided

Consumables

Carefully selected materials for predictable and cost-effective farming

Fertigation unit

Automatically mixes precise nutrition blend for each shelf

Growing Area 1

IT-managed climate; irrigation and lightning; sensor monitoring

Growing Area 2

Using two growing areas allows plants to be grown at staggered stages in their fruiting cycle so farmers can continuously harvest strawberries, thus maximizing productivity and yields

iFarm’s integrated full service also includes project design, installation of iFarm Berries system, and farm launch

Management system

Business-oriented user-friendly software suite with free updates

Hardware automation

Integrated secure system

4

7

6

5

3

2

1

- Seeding Area

Manual or automated ergonomic process with all the materials provided

5. Consumables

Carefully selected materials for predictable and cost-effective farming

3. Fertigation unit

Automatically mixes precise nutrition blend for each shelf

6. Growing Area 1

IT-managed climate; irrigation and lightning; sensor monitoring

7. Growing Area 2

Using two growing areas allows plants to be grown at staggered stages in their fruiting cycle so farmers can continuously harvest strawberries, thus maximizing productivity and yields

iFarm’s integrated full service also includes project design, installation of iFarm Berries system, and farm launch

2. Management system

Business-oriented user-friendly software suite with free updates

4. Hardware automation

Integrated secure system

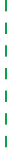

Farm size

Produce

Yields per year

from 60 m2 floor space

strawberries with following organoleptic properties: sweet berry, hard fruit, cone shape with noticeable shine, Brix level >10°

4 in each area

Hydroponics technology

drip irrigation method without recirculation of nutrient solution

Planting method

Growtune Management System

Automated processes

- available crop assortment

- 2 strawberry varieties

- phyto lighting

- mixing nutrient solution

- irrigation with constant control of EC and pH levels of nutrient solution

- maintaining optimal climatic parameters

- maintaining the correct CO2 level

- opening and closing bumblebee hive exits

Manual processes:

- substrate saturation

- planting seedlings

- monitoring plants condition; phytomonitoring

- control of EC and pH levels of nutrient solution

- treatment with fungicide protection

- entomophagous operation

- controlling amount of berries per bush

- peduncles support

- picking and packing strawberries

- disinfecting equipment and rooms

- equipment maintenance

seedlings are planted in holes of bulk mats

To learn more about ultimate vertical farming technology, schedule an online meeting!

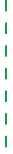

Estimate your potential monthly harvest with iFarm Berries

We offer consultations to help you choose the assortment of cultures that best fits your region and market

Floor area, sq.m

Height, m

Plants quantity

300

4.5

2 664

Yield per month, kg

457

500

4.5

4 662

799

1 000

4.5

11 322

1 941

2 500

4.5

29 970

5 138

Growing area, sq.m

475

831

2 004

5 298

Floor area, sq.m

300

500

1 000

2 500

Height, m

4.5

4.5

4.5

4.5

Growing area, sq.m

475

831

2004

5298

Plants quantity

2664

4662

11322

29970

Yield per month, kg

457

799

1941

5138

Advantages of iFarm vertical farm technologies

-

Always-fresh produceVertical farms can be situated in urban areas so that produce can be delivered to retailers and consumers when it's at its freshest

Always-fresh produceVertical farms can be situated in urban areas so that produce can be delivered to retailers and consumers when it's at its freshest -

Pesticide-freeThe closed air cycle and controlled microclimate inside the farm avoid the use of non-biological pesticides, herbicides and acaricides

Pesticide-freeThe closed air cycle and controlled microclimate inside the farm avoid the use of non-biological pesticides, herbicides and acaricides -

Fast scalingFarms can be built in any configuration from 500 to more than 20 000 sq.m. It takes just weeks to design, build, and start growing

Fast scalingFarms can be built in any configuration from 500 to more than 20 000 sq.m. It takes just weeks to design, build, and start growing -

Saving spaceVertical tiers maximize space. With no need for soil, farms can be installed in industrial premises, warehouses and workshops

Saving spaceVertical tiers maximize space. With no need for soil, farms can be installed in industrial premises, warehouses and workshops -

Environmental friendlinessShort supply chains drastically reduce carbon footprints, and controlled environment agriculture methods don't impact the ecology

Environmental friendlinessShort supply chains drastically reduce carbon footprints, and controlled environment agriculture methods don't impact the ecology -

Cost savingsProduction, processing, warehousing and storage in one location cuts expenditure. With iFarm Growtune software, no highly-qualified employees are needed

Cost savingsProduction, processing, warehousing and storage in one location cuts expenditure. With iFarm Growtune software, no highly-qualified employees are needed -

Easy cultivationProcess automation and farm management software reduces the risks of a vertical farming business and maximizes yields

Easy cultivationProcess automation and farm management software reduces the risks of a vertical farming business and maximizes yields -

Water savingiFarm vertical farms consume 90-95% less water than traditional agriculture and translucent greenhouses

Water savingiFarm vertical farms consume 90-95% less water than traditional agriculture and translucent greenhouses

Go through your options in a meeting with your project manager

Learn about iFarm technology

Estimate the investment requirements for your project

iFarm provides free project evaluation based on individual parameters

Get a business plan and farm design

Contract market research from iFarm with a financial model calculation and project design

Launch your farm installation

Sign the supply contract, and iFarm’s installation team will arrive to fully set up your vertical farm and teach you to operate it

An Easy Way to Start Your Vertical Farm

1/

2/

3/

4/

5/

6/

Plant the first seeds

Plant the first batch of crops using our agricultural technology with the help of the Growtune software’s checklists

Stay in touch to receive full support

Source consumables, benefit from the iFarm Growtune platform, and consult with a Support team for all your needs

All iFarm technologies for automated vertical farming

Choose a cutting-edge vertical farming system with full-service support for commercial production of fresh, healthy foods cost-effectively.

Grow salads and herbs in a controlled environment with Nutrient Film Technique hydroponics for plant irrigation. Automated, scalable technology with a wide range of crops available to grow.

Fully-automated hydroponic vertical farming solution for salads and herbs. Enables ultimate plant density and energy savings, with the minimum manual labor.

Cultivate microgreens at industrial scale with a vertical farming technology based on the Flood & Drain irrigation method, and get up to 55 harvests per year.

SaaS Platform for managing automated vertical farms, allowing you to achieve high-quality yield at predictable terms and reduce the cost of produce.

Grow full-flavored strawberries year round on a vertical farm using drip irrigation and pollination with bumblebees.

iFarm Automated farm system for commercial cultivation of vegetables in controlled environment.

Cutting-edge technology for rapid, efficient, and reliable tree seedling growth, ensuring strong, healthy forests in any climate, from arid deserts to extreme environments.

Compactly packed iFarm Leafy Greens system for hyperlocal production of salads and herbs. Can be installed as an individual spot or container cluster.

Submit the form for a detailed presentation of iFarm Leafy Greens Stackgrow technology

By clicking SUBMIT, you agree to the processing of personal data and to the privacy policy